MES Manufacturing Execution System |

|||||||||||||

| Production Management Software |

|||||||||||||

|

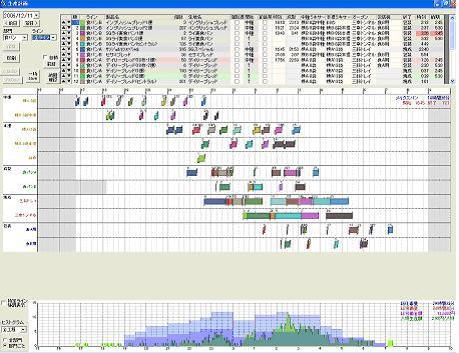

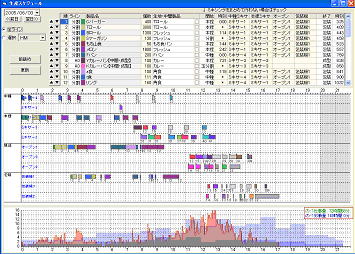

For Small Bakery, Retail Bakery To scientific production from the experience and feeling “Ad Libitum”, affordable even for small/medium factory and to collect an initial cost certainly. Scheduling display : The process optimization by visualization is displayed

|

|||||||||||||

|

“Ad Libitum” that visualize complicated factory and control production optimized

|

|||||||||||||

Whole Factory Display Individual Line Display   |

|||||||||||||

| Visualizing Factory solute Production Problem OPTIMIZATION Technova's "Ad Libitum" shows the precise Production Schedule

which is planed based on each production condition of product immediately

after in putting the production order. "The visualizing factory"

by Gant Chart and Histogram and so on, helps to get the situation in perspective

plainly the factory condition and problems. Productivity will be improved

easily by changing production order (sequence), selection production resources

by watching the display of "ad libitum". Good labor efficient

Schedule is made by the production order, which is determined, adjusting

the relation of worker supply (purple), whole job volume (pink) and line

job volume (green). When you change the production order of products, you

can recognize changing time length of the make span (the time length from

start to finish of production). Therefore you can make a shorter production

schedule of make span easily controlling a necessity of labor volume. It

makes an obvious improvement of the productivity of factory. During making

production schedule, watching not only whole factory screen but also each

production line makes better efficient production. Ad libitum realize the

visualizing factory also visualizing job and labor. |

|||||||||||||

|

|||||||||||||

|

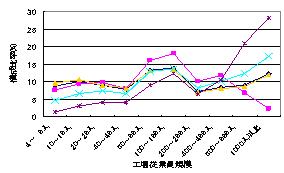

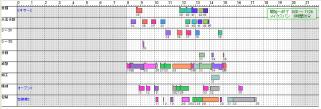

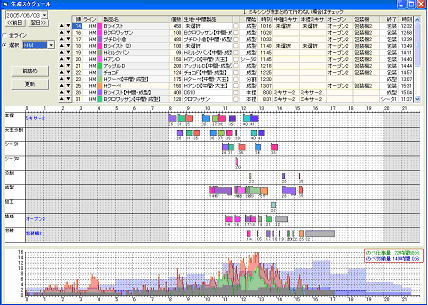

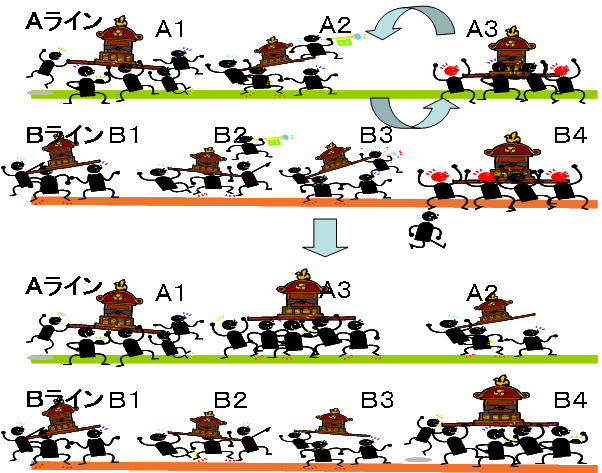

Equalization of the worker number A necessary worker number changes during production in the multiple kind productions. In the case of the multiple lines the worker total number fluctuates more largely. As the “Ad libitum” overlays to detailed histogram the change of work quantity and the supply labor quantity in the monitor, a planner is able to judge the excess and deficiency of a labor at a glance. As the production order can be changed easily, a workload is adjusted by the combination of work and the labor quantity and work quantity can be matched. This factory is composed of 3 lines of a divider, HM, and AD and a vertical axis is time and a horizontal axis is a worker number. The pink part is the change of the job quantity for each after one minute based on production command. The supply labor quantity of the blue part is shown with the number of persons. The place where job quantity and regular worker overlapped is changing in gray color. The worker number of the green part of the right histogram becomes needed every time at the time of the production of a left Gantt chart, if the divider line is taken as an example. All the necessary worker numbers that combined A, B, C line are shown with a pink part. Accordingly a blue part increases when labor force is supplied excessively. If it adjusts between lines not to an independent line like this, it can decrease the labor force of the whole factory. |

|||||||||||||

|

Individual Production line Gant Chart Individual line necessary labor volume Histogram

|

|||||||||||||

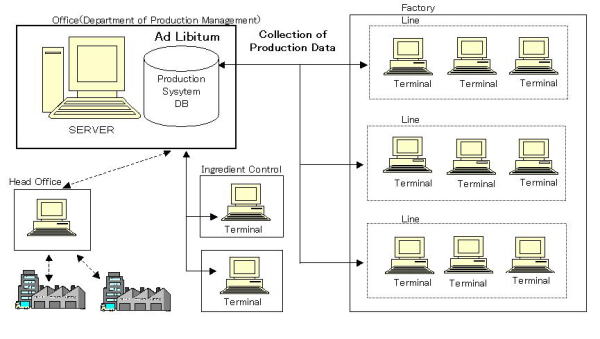

| MES(Manufacturing Execution System): Ad Libitum has

been developed in mainly food industry. Compare with electric goods, car and

chemical plants, majority of food factory has more complicate and more obscure

condition of production factors which experience and scent exist remain still

now. There few scheduler (production plan software) works well in a complicate

food factory especially bakery. Many backbone system such as ERP (Enterprise

Resource Planning) and MRP (Material Requirements Planning) state that this

system has a production management function, however these system has

ingredients control function and products stock control function at most. If

they have a schedule function, almost of their scheduler are not enough to use

in a complicated food factory.

MES inform business

data from business system like ERP to production site, and receive production

data from production site. MES become more and more important as not only for

factory (production site) but also information system between management and

factory. So far isolated data in production site are scattered in even same

factory, there is no system, which connect smoothly between business system and

factory system. |

|||||||||||||

|

|||||||||||||

|

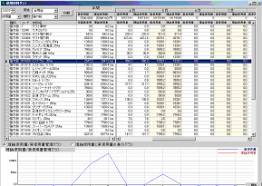

Effect of “Ad Libitum” introduction |

|||||||||||||

| Customers Bakeries, Food, Frozen foods, Frozen dough, Ice cream corn, Confectionary,

Flour mixes, Fillings, Premixed flour, Beverage, Chemical products, Cardboard container, Glass container, Concrete, etc. “Ad Libitum” can be easily customized for almost all customers. |

|||||||||||||

| Ad. Libitum catalogue Improving the Productivity of Food Manufactureing through Information Technology -Case Studies of Medium sized Food Factories- アドリブ導入事例オイシス様 アドリブ導入事例白石食品工業様 アドリブ導入事例サンジェルマン様 デスクトップに保存してご覧ください。印刷もできます。 |